Impact forces shape our daily lives—from athletic collisions to car crashes. Understanding how materials absorb and dissipate energy is revolutionizing safety design across industries.

🔬 The Fundamental Physics of Force Absorption

When an object collides with another, kinetic energy must go somewhere. This simple principle drives decades of engineering innovation aimed at protecting humans, products, and structures from devastating impacts. Force absorption isn’t about making things harder—it’s about making them smarter.

At its core, impact absorption relies on converting kinetic energy into other forms: heat, sound, or deformation. The materials that excel at this transformation extend the time over which force acts on an object, reducing peak acceleration. This concept, known as impulse-momentum theory, explains why airbags save lives and why packaging foam protects fragile electronics.

The mathematical relationship is elegantly simple: Force equals mass multiplied by acceleration (F=ma). By increasing the time during which deceleration occurs, engineers reduce the peak force experienced. A car crumpling over several milliseconds generates far lower forces than one that stops instantaneously against a rigid wall.

Energy Dissipation Mechanisms

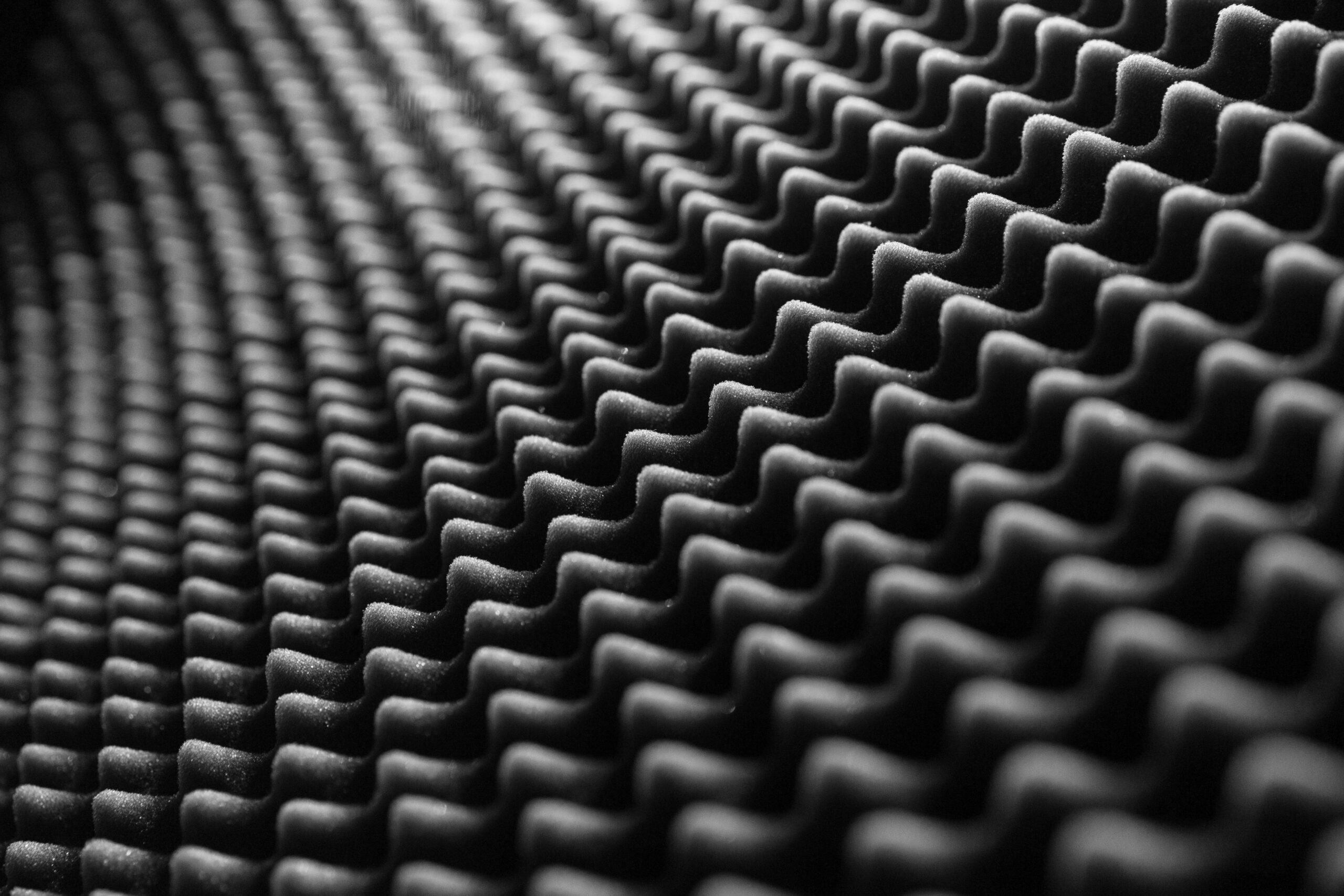

Modern materials employ multiple strategies to absorb impact energy. Cellular structures like foams compress, allowing air to escape through tiny pores while the material deforms. Viscoelastic polymers convert kinetic energy into heat through internal friction. Composite materials combine multiple mechanisms, optimizing performance across different impact velocities and energies.

The effectiveness of these mechanisms depends heavily on material properties: density, elasticity, yield strength, and energy absorption capacity. Engineers balance these characteristics to create solutions tailored to specific applications, from motorcycle helmets to building earthquake dampeners.

🏗️ Material Science Breakthroughs Transforming Safety

Recent innovations in materials science have unlocked unprecedented capabilities in impact protection. Traditional materials like steel and concrete remain important, but advanced composites, metamaterials, and bio-inspired designs are redefining what’s possible.

Advanced Foam Technologies

Modern foam structures extend far beyond simple polyurethane. Engineered cellular geometries optimize compression behavior, creating materials that stiffen progressively as they compress. This property, called strain-rate sensitivity, ensures maximum energy absorption without catastrophic failure.

Multi-density foams layer materials with different compression characteristics, creating absorption profiles matched to specific impact scenarios. Helmet manufacturers use soft outer layers to handle low-energy impacts while stiffer inner cores protect against severe collisions.

Shear Thickening Fluids

These remarkable substances flow like liquids under normal conditions but instantly solidify when struck rapidly. Armor manufacturers incorporate shear thickening fluids into flexible protective gear, creating equipment that moves naturally yet hardens on impact. The technology found early adoption in military applications and now appears in consumer products ranging from motorcycle gear to smartphone cases.

Graphene and Carbon Nanostructures

Graphene’s extraordinary strength-to-weight ratio makes it ideal for impact applications where mass matters. Researchers are developing graphene-reinforced composites that absorb tremendous energy while remaining lightweight. Carbon nanotube arrays can compress repeatedly without permanent deformation, making them candidates for reusable impact protection systems.

🚗 Automotive Safety: Where Impact Science Meets Reality

Nowhere is impact absorption more critical than automotive design. Modern vehicles represent sophisticated energy management systems, carefully engineered to protect occupants during collisions.

Crumple zones transform vehicle front and rear sections into controlled deformation zones. These areas collapse predictably during impacts, absorbing energy that would otherwise transfer to passengers. Advanced high-strength steels provide structural integrity while allowing designed collapse patterns.

The Evolution of Restraint Systems

Airbag technology exemplifies impact science in action. Sensors detect sudden deceleration and deploy fabric bags within milliseconds. The inflated bag increases contact area and extends deceleration time, dramatically reducing forces on the human body. Modern vehicles may contain ten or more airbags positioned strategically throughout the cabin.

Seatbelt pre-tensioners and load limiters add further sophistication. Pre-tensioners tighten belts instantly during crashes, preventing occupant movement. Load limiters then allow controlled belt extension, preventing chest injuries from excessive restraint forces. This two-stage approach optimizes protection across varying collision severities.

Pedestrian Protection Systems

External impact absorption is gaining attention as engineers address pedestrian safety. Active hood systems detect collisions with pedestrians and lift the hood several inches, creating a deformation zone that reduces head impact forces. Energy-absorbing bumpers and deformable front-end structures further minimize injury severity.

⚡ Sports Equipment: Protecting Athletes Through Innovation

Athletic performance and safety once seemed contradictory goals. Modern equipment demonstrates that proper impact management enhances both. From helmets to playing surfaces, sports technology leverages advanced materials and biomechanical understanding.

Helmet Design Revolution

Contemporary helmets employ multi-layered systems addressing both linear and rotational impacts. Outer shells distribute forces across wider areas. Inner liners compress to absorb energy. Slip-plane technologies allow controlled rotation between layers, reducing dangerous rotational accelerations linked to concussions.

Some designs incorporate rate-sensitive materials that remain soft during normal wear but stiffen during impacts. Others use lattice structures optimized through computer simulations to provide directional protection matching common impact vectors for specific sports.

Athletic Footwear Technology

Running shoes demonstrate sophisticated impact management in compact form factors. Midsole foams balance cushioning with energy return, protecting joints while maintaining efficiency. Geometric designs like Nike’s Zoom X foam and Adidas’s Boost technology create cellular structures optimized for repetitive loading.

Basketball shoes face different challenges, requiring lateral stability alongside vertical impact absorption. Multi-density midsoles and external support structures distribute forces while preventing ankle injuries. Computer modeling now predicts how designs perform under realistic athletic movements.

🏢 Structural Engineering: Buildings That Absorb Seismic Energy

Earthquake engineering applies impact absorption principles at massive scales. Buildings in seismic zones incorporate systems that dissipate ground motion energy, preventing structural failure and protecting occupants.

Base Isolation Systems

These technologies separate buildings from ground motion using flexible bearings or sliding mechanisms. During earthquakes, the ground moves but the building remains relatively stable. Elastomeric bearings combine rubber and steel plates, compressing and shearing to absorb energy. Friction pendulum systems allow controlled sliding while self-centering through gravitational restoring forces.

Tuned Mass Dampers

Massive pendulums installed at building tops counteract structural oscillations. The Taipei 101 tower features a 660-ton damper suspended from the 92nd floor. As the building sways, the damper moves oppositely, reducing amplitude. Hydraulic cylinders dissipate energy through fluid resistance, preventing resonant oscillations that could cause structural damage.

Buckling-Restrained Braces

These structural elements yield during earthquakes, absorbing seismic energy through controlled deformation. Unlike conventional braces that buckle unpredictably, buckling-restrained braces maintain strength while dissipating energy. After earthquakes, damaged braces can be replaced while the primary structure remains intact—a revolutionary approach to seismic resilience.

📱 Consumer Electronics: Protecting Delicate Technology

Smartphones, tablets, and laptops face constant drop risks. Manufacturers employ various strategies to protect fragile components, particularly glass screens and sensitive electronics.

Chemically strengthened glass undergoes ion-exchange treatments that create surface compression layers. These resist crack formation and propagation, surviving drops that would shatter untreated glass. Gorilla Glass and similar products have become industry standards, enabling increasingly large screens without proportional fragility increases.

Internal Suspension Systems

Modern devices incorporate internal structures that suspend critical components away from external surfaces. Rubber grommets and foam cushions isolate circuit boards from impact forces. Some designs use nested structures where outer frames deform first, protecting inner electronics.

Case manufacturers leverage similar principles in aftermarket protection. Dual-layer cases combine rigid outer shells with energy-absorbing elastomer liners. Air cushion technologies place pockets at corners where drop impacts typically concentrate. These designs demonstrate how consumer products can adopt aerospace-level impact engineering.

🔬 Biomimicry: Nature’s Impact Absorption Solutions

Evolution has produced remarkable impact-resistant biological structures. Engineers increasingly look to nature for inspiration when designing protective systems.

Woodpecker Skull Mechanics

Woodpeckers strike trees at forces exceeding 1,000 g without brain injury. Their skulls feature spongy bone that absorbs impact energy, minimal fluid space preventing brain movement, and specialized muscle arrangements that distribute forces. Helmet designers have adopted similar principles, creating liners with directional structures matching biological solutions.

Mantis Shrimp Impact Systems

These marine creatures strike prey with forces comparable to gunshots, yet their appendages don’t shatter. Researchers discovered composite structures with periodic architecture that deflects cracks. This discovery inspired new ceramic composites for armor and aerospace applications, demonstrating how cross-scale biology informs engineering.

Conch Shell Architecture

The strombus gigas conch shell resists crushing through crossed-lamellar microstructures. Alternating layers of calcium carbonate arranged at specific angles create exceptional toughness. This architecture prevents crack propagation, inspiring layered composite designs for protective equipment and structural applications.

⚙️ Computational Tools Accelerating Design Innovation

Computer simulations have transformed impact engineering from trial-and-error to predictive science. Finite element analysis models material behavior under complex loading conditions, allowing designers to optimize structures before physical prototyping.

Modern software simulates impacts at multiple scales simultaneously. Macro-level models predict overall structural response while micro-level analyses examine material deformation and failure mechanisms. This multi-scale approach reveals design opportunities invisible to single-scale analysis.

Machine Learning Applications

Artificial intelligence is entering impact design workflows. Neural networks trained on thousands of simulations can predict performance from design parameters, dramatically accelerating optimization. Generative design algorithms explore vast solution spaces, proposing structures human designers might never conceive.

Some systems combine simulation with experimental data, refining predictions as real-world testing validates or corrects computational models. This iterative approach continuously improves accuracy, making virtual testing increasingly reliable for certification purposes.

🌍 Sustainable Impact Protection: Balancing Safety and Environment

Environmental concerns are reshaping impact absorption technology. Traditional petroleum-based foams and composites face pressure from sustainability initiatives. Researchers are developing bio-based alternatives that maintain performance while reducing environmental footprints.

Mycelium-based foams use fungal networks to create cellular structures comparable to synthetic foams. These materials are renewable, biodegradable, and require minimal energy to produce. Early applications include packaging, with potential expansion into construction and protective equipment.

Recyclable Composite Development

Traditional composite materials resist recycling because constituent materials can’t be separated. New thermoplastic composites melt and reform like conventional plastics while maintaining performance advantages. These materials enable circular economy approaches where end-of-life products become feedstock for new manufacturing.

Natural fiber composites combine plant-based fibers with bio-resins, creating impact-resistant materials from renewable sources. Flax, hemp, and bamboo fibers provide mechanical properties approaching synthetic alternatives with significantly lower environmental impacts.

🚀 Future Frontiers in Impact Science

Emerging technologies promise to revolutionize impact protection further. Adaptive materials that modify properties in response to threats, self-healing structures that repair impact damage, and nano-engineered surfaces with programmable mechanical behaviors represent the cutting edge.

4D printing adds temporal dimensions to 3D printing, creating structures that transform after manufacturing. Impact-responsive 4D printed materials could deploy protective features only when needed, reducing weight and bulk during normal use.

Smart Materials Integration

Embedded sensors and actuators transform passive protection into active systems. Imagine helmets that detect imminent impacts and deploy additional protection milliseconds before collision. Such systems could adjust stiffness based on impact severity predictions, optimizing protection across unprecedented threat ranges.

Metamaterials with negative Poisson’s ratios expand rather than contract when stretched, creating unusual mechanical behaviors useful for impact applications. These auxetic materials become thicker when stressed, potentially offering superior penetration resistance and energy absorption.

💡 Bridging Research and Real-World Implementation

The gap between laboratory innovations and commercial products remains significant. Manufacturing scalability, cost constraints, and regulatory requirements slow adoption of promising technologies. Successful implementation requires collaboration between researchers, manufacturers, and regulatory bodies.

Standardized testing protocols ensure new materials meet safety requirements. Organizations like ASTM International and ISO develop methodologies for evaluating impact performance, creating common languages for comparing technologies. These standards accelerate adoption by providing clear performance benchmarks.

Cost reduction through economies of scale eventually brings advanced materials to mass markets. Technologies that debut in premium applications gradually become affordable for broader use. This democratization of safety technology has saved countless lives as innovations pioneered in motorsports and aerospace reach everyday consumer products.

🎯 Designing for Multiple Impact Scenarios

Real-world products face diverse impact threats. Effective designs address multiple scenarios simultaneously—a challenge requiring sophisticated engineering. Helmets must protect against both high-velocity penetration and broad-surface impacts. Vehicle structures must manage frontal, side, and rear collisions with varying speeds and impact objects.

Multi-objective optimization algorithms help engineers balance competing requirements. These computational tools identify designs that perform well across entire threat spectra rather than excelling at single scenarios. The result is robust protection that doesn’t sacrifice performance in one area to excel in another.

Impact absorption technology represents a fascinating intersection of physics, materials science, and engineering creativity. From molecular-level material behavior to building-scale seismic protection, the principles remain consistent: extend impact duration, distribute forces, and convert kinetic energy into less harmful forms. As research continues and new materials emerge, our ability to protect people and property from impact forces will only improve, creating a safer world through intelligent design and scientific understanding. The future promises materials that are lighter, stronger, and more adaptive—transforming how we approach safety across every aspect of modern life.

Toni Santos is a workplace safety researcher and human factors specialist focusing on injury prevention logic, mechanical body models, productivity preservation goals, and workforce longevity impacts. Through an interdisciplinary and evidence-based lens, Toni investigates how organizations can protect human capacity, reduce physical strain, and sustain performance — across industries, roles, and operational environments. His work is grounded in understanding the body not only as a biological system, but as a mechanical structure under load. From ergonomic intervention strategies to biomechanical modeling and fatigue mitigation frameworks, Toni uncovers the analytical and preventive tools through which organizations preserve their most critical resource: their people. With a background in occupational biomechanics and workforce health systems, Toni blends movement analysis with operational research to reveal how work design shapes resilience, sustains capacity, and protects long-term employability. As the strategic lead behind Elyvexon, Toni develops evidence-based frameworks, predictive injury models, and workforce preservation strategies that strengthen the alignment between human capability, task demand, and organizational sustainability. His work is a tribute to: The science of safeguarding workers through Injury Prevention Logic and Systems The structural understanding of Mechanical Body Models and Biomechanics The operational necessity of Productivity Preservation Goals The long-term mission of ensuring Workforce Longevity and Career Resilience Whether you're a safety leader, workforce strategist, or advocate for sustainable human performance, Toni invites you to explore the proven principles of injury prevention and capacity protection — one system, one model, one career at a time.